The history of 3D printing 3D begins in 1976 with inkjet printing, which transformed into printing with materials in 1984. Since then, everything has been manufactured: from organs such as a kidney in 2002, a leg prosthesis which helps a person to walk in 2008, to printed blood vessels made with bio-printers in 2009.

In 2011, the industry went a step further by creating the first plane and the first car. At present, 3D printing can be applied to all fields, such as automotive, medicine, space, industry, food or education.

In the near future, it is estimated that there will be a 3D printer in every home, as common as today’s household computers or dishwashers.

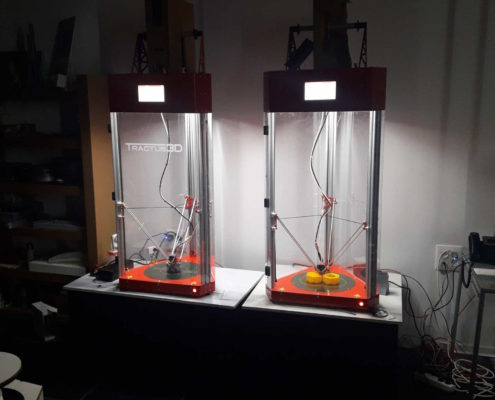

Serisan Not wanting to be left behind, Serisan has already incorporated 3D printers in order to offer technology and differentiation to our customers.

Types of 3D printers

3D printers are classified according to the technology they use, defined as:

- De Stereolithography (SLA) also called “resin”, were the first to be used.

- Laser Selective Sintering (SLS) born in the 1980s, the main difference with SLA with these you can use a large number of powdered materials, such as ceramics, polystyrene or nylon…

- Injection printers are the most similar to everyday paper printers.

- Molten Material Deposition Printing (FDM), also known as Fused Filament Fabrication (FFF) uses a technology that deposits molten polymer on a flat, layer by layer basis.

We find several types of FDM printers though the most widespread are Cartesian and Delta:

- Cartesian printers are the most common on the market, their name comes from the coordinate system they use. This is a dimensional system that determines where and how to move in three dimensions and are formed by two perpendicular arms. As a disadvantage they are slower than Delta printers but are easier to calibrate and adjust.

- Delta printers are distinguished because they have a circular print bed, which remains fixed providing greater accuracy. They have three articulated arms that form a triangular configuration. The print head moves in three dimensions. The advantage of these printers is that they are faster than Cartesian, more precise and stable. In addition, the manufacturing height can be increased without reducing quality.

- Polar printers use polar coordinates to print.

- Robotic arms are used mainly in the construction sector and research on them is continued to improve them.

After this brief summary about the classification of printers and their types we are going to talk about the FDM or FFF Delta type technology printers, the printers that Serisan works with Serisan.

3d printer for prototyping

Materials

There are currently a lot of variety of materials: ABS, PLA, PETG … The materials used by Serisan for the Delta printer are PLA filaments made from biodegradable corn starch, composed of plant components that do not emit gases when melting.

PLA filaments can be found in a variety of colors, although new combinations of materials such as PLA with metallic powder or wood fibers are increasingly created.

The pieces that are obtained, are not always rigid, you can print flexible pieces such as bracelets, shoes, clothes…

What is the 3D printing process?

Preprocessed:

First, the 3D design of the object we want to reproduce is created. The design can be downloaded from an image bank such as Thingiverse Thingiverse or self-designed.

Subsequently, a printing software such as Simplify 3D is used. Different settings are used to take into account variables such as thickness of the layer, the printing speed, the filling and the size of the piece. This information is transmitted through its programming language, Code G or G-Code, which determines a trajectory from which the piece is created.

Indications:

In order for the printer to operate, the nozzle must reach a temperature of 200 degrees. The filament rolls melt and are expelled by the nozzle, they solidify as they take the form of each layer.

The system calculates how long it will take to print a part, and once the order is launched the printer can print continuously, day and night.

The printer used by Serisan has a heated base that helps the object stay well glued and does not give problems of grinding (bitten filament).