3D ROBOT FOR THE MANUFACTURE OF MODELS

When we talk about 3D robot, are we thinking of 3D printer? It is possible, because although there is a difference both elements seek the same thing: manufacturing a product to meet a market need.

It is clear that when we pronounce the word 3D robot, unconsciously we are thinking of high end technology. It is also true that this sophisticated machinery is going to replace thousands of jobs in the future, but also very true that the world cannot stop turning, and companies that do not keep innovation in mind, have an expiration date

When, at the end of 2015, we decided to incorporate a 3D robot to make models, we saw a new line of business open for our company, the realization of forms without limits to size, something that very few companies could do. However, all that glitters is not gold, the manufacturing process is expensive and specialized technicians are needed to handle the robot.

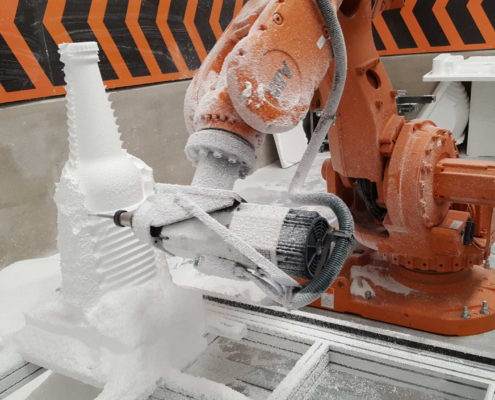

Robot 3d its main function is the devastated parts in porexpan to create prototypes, molds and corporeal figures

Manufacturing a form with a 3D robot

- For the manufacture of a 3D form, it is necessary to start from a good original, digitized by scanner 3d, an apparatus that captures the shape and characteristics of any type of volume or environment and builds a three-dimensional model by means of specific software. With a single capture we will not be able to obtain the exact reproduction of our prototype, so several scans from different positions are necessary to gather the maximum amount of information from the object.

- The next step is to prepare the “strategy”, to give the robot instructions as to how to break down the piece, as can be seen in the video. Then, once the figure is sculpted, it is given a polyurea finish, a synthetic polymer that hardens the prototyping material, combining 2 components which dry very quickly, applied with a special pistol.

- The next phase is sanding the polyurea, smoothing the existing defects and deformations in the model.

- The coloring of the airbrushed figure will lead us to a realistic finish, similar to that found in a wax museum.

- At the end of the process, we apply a layer of gloss varnish with UV protection, to give maximum durability to the object outside.

Corporeo manufactured with robot 3d, after scanning the piece

Conclusion

It is clear that manufacturing a 3D form is not a simple process, since manufacturing a prototype is expensive. To optimize the product value, the ideal is to make several reproductions, as the prototype allows you to make a mold and cover the cost in manufactured units.

With the technological advance of 3D printers, this will be achieved in the not too distant future, at least in smaller sizes; in products over 1 meter high, we will continue to give the artisan finish (airbrushing), until the method evolves.