From the beginnings

1st phase of Serisan

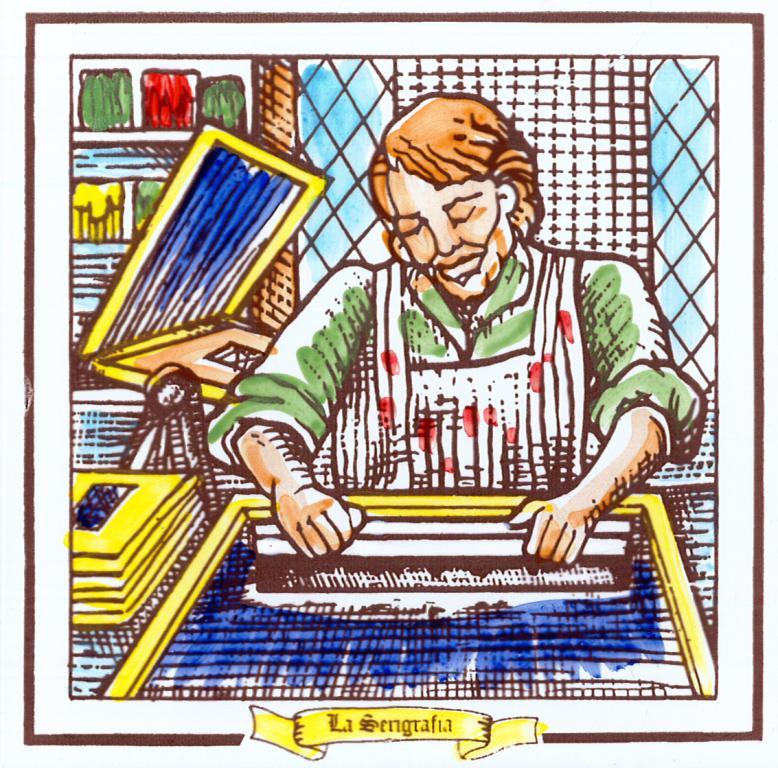

As its name suggests, Serigrafía Santander started in the field of screen printing in 1973.

There was high initial demand for graphics on materials exposed to the outdoor elements, that by other methods would not guarantee resistance and durability to abrasion or sunlight.

In early 1986, computerized technology is incorporated into graphic arts, with the acquisition of the first cutting plotter (38cm width).

With this technological breakthrough there is a great leap in the manufacture of digitally die-cut color adhesive vinyl texts. Subsequently, a digitizer is incorporated, along with the first computer equipped with logos and fonts creation software. As such, there is a great leap in the quality, format and agility of our graphic signage creation.

In 1988, we acquire a cutting plotter that doubles cutting speed and can work with 1m panel width formats.

![]()

From the beginnings

2nd phase of Serisan

With the acquisition of the first digital machine equipped with printing and cutting software in 1991, the company embarked on its trajectory in the field of digital printing, able to print quality photography on a wide range of materials without the need for templates, photoliths or other preparations.

Between 1998 and 2003, Serisan enters into a collaboration agreement for Spain with a German manufacturer of large format printing plotters. The agreement attempts to incorporate and test the latest techniques, machinery and inks developed by the manufacturer, with Serisan acting as its research and testing center.

![]()

Our History

from the Beginnings

3rd Stage of Serisan

In June, 2005, we reach a milestone in the field of digital printing by acquiring a new direct digital flatbed printing system with UV cured ink technology. In 2008, we acquired the latest digital printing macro-plotter, a digital printing machine with eco-solvent technology. Print quality, speed and agility improved with the acquisition of this plotter able to print single pieces. By mid 2010, the acquisition of a new direct printing machine doubles quality (1200 dpi resolution) and triples production speed. In addition we purchase an automated digital cutting table to complement the printing line-up. Thus giving added value to all our digital personalization work.

In 2013 a new cutter / mill is acquired to complement the digital printing machines. And in 2016, we added the latest in printing, with the possibility of printing double layers of white, gloss or matt selective varnish, 3D varnish and prints up to 3, 20 meters wide.